MACHINE TOOLS TRADERS

Featured Products

Highest quality standards are achieved through the implementations of latest technology, decades of experience and everlasting moral values , which have helped us to retain our customers as well as multiply them.

Welcome to MACHINE TOOLS TRADERS

Cnc Trainer Lathe Roduction Typetl

FEATURES :

- CNC Slant Bed Bench Turning Centre

- 8 Station Indexing Tool Post

- SIEMENS 802D SOLUTION LINE control / FANUC Oi Mate Programming and Industrial type Control Panel with

10" colour monitor with closed loop servo motor control with further option of linking to CAD/CAM and FMS

(Flexible Manufacturing System).

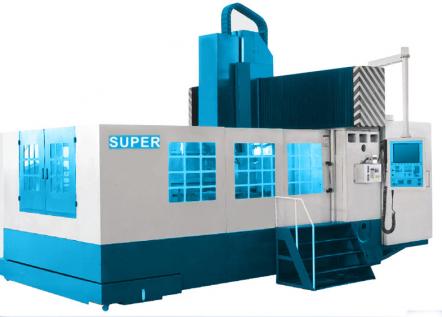

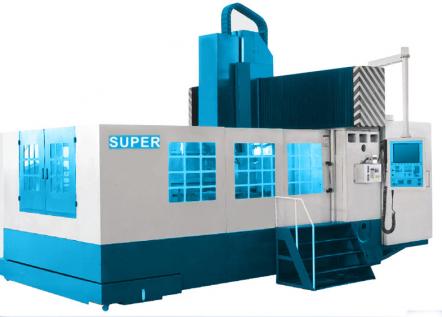

Fixed Beam Gantry Machining Centre

Description / Specification of Fixed Beam Gantry Machining Centre

We are involved in offering a wide range of Fixed Beam Gantry Machining Centre to our most valued clients. Our range of these are widely appreciated by our clients which are situated all round the nation. We offer our range of it at most affordable prices.

We introduce ourselves as an eminent trader and supplier of an extensive array of Fixed Beam Gantry Machining Centre. Prior to dispatch, our quality controllers run numerous tests on the entire range on various parameters of quality and durability. The offered equipment is manufactured using superior quality components with the aid of sophisticated techniques at the vendors' end. Moreover, our precious clients can purchase it in different technical specifications at reasonable price from us within promised time frame.

Features:

Sturdy design

Highly durable

Application specific design

Drill Cum Tapping Machining Center

Description / Specification of Drill Cum Tapping Machining Center

We are involved in offering a wide range of Drill Cum Tapping Machining Center to our most valued clients. Our range of these are widely appreciated by our clients which are situated all round the nation. We offer our range of it at most affordable prices.

We introduce ourselves as an eminent trader and supplier of an extensive array of Drill Cum Tapping Machining Center. Prior to dispatch, our quality controllers run numerous tests on the entire range on various parameters of quality and durability. The offered equipment is manufactured using superior quality components with the aid of sophisticated techniques at the vendors' end. Moreover, our precious clients can purchase it in different technical specifications at reasonable price from us within promised time frame.

Features:

Sturdy design

Highly durable

Application specific design

Slant Bed Cnc Lathe Cl Series

FEATURES:

- CNC SLANT BED LATHES WITH RIGID CAST-IRON STRUCTRE HARDENED(50-52HRC) AND GROUND GUARANTEE HIGH PRECISION AND STABILITY.

- THE MACHINE BED IS MADE OF HEAT STABILISED CAST-IRON.

- VARIOUS CONFIGURATION ARE AVAILABLE WITH SINDLES FROM ASA 5" TO ASA 15",POWER UP TO 30KW AND TUMING LENGTH UP TO 3000MM

- A WIDE RANGE OF OPTIONS AND ACCESSORIES ALLOW THE MACHINE TO BE HIGHLY CUSTOMISED FOR VERY ACCURATE AND RELIABLE MACHINING.

Flat Bed Cnc Lathe Cke Series

FEATURES:

- FANUC Oi MATE CNC CONTROL

- CONSTRUCTION CASTING MOLDED WITH RESIN SAND OF BED, HEADSTOCK, SADDLE PLINTH etc.

- TURCITE-B COATED ON, MAKING SURFACES BETWEEN SADDLE AND GUIDEWAYS.

- PRECISION BALLSCREW, HIGH RIGIDITY PRECISION COMPOUND BEARING ENSURE ACCURATE POSITIONING &EFFICIENT DRIVING. CENTRALIZED OIL LUBRICATOR PROVIDING FORCED AUTO. LUBRICATION ONTO BALLSCREW, MATING SURFACES.

- HIGH SPINDLE SPEED WITH WIDE VARIABLE SPEED RANGES. LOW NOISE UNDER 80db. CKE-Z SERIES MACHINE ADOPTING THE SMART AUTOMATIC GEAR CHANGING MECHANISM ENABLES AUOTMATIC SPEED CHANGES AMONG LOW, MEDIUM, HIGH SPEED RANGES WITHOUT TURNING OFF THE MACHINE. CKE-i SERIES WITH INDEPENDENT SPINDLE STRUCTURE AND FREQUENCY CONVERTED MOTOR OR SERVO MOTOR ENABLES HIGH SPINDLE SPEED AND STEPLESS SPINDLE CHANGING

- FLEXIBLE CONTROL PANEL ENABLES CONVENIENT TOOL SETTING.

Our Vision

* To embrace new technologies and methods. * To give unsurpassed products and services to the clients. * To constantly look for improvement and changes.